| Model | 230 | ||||

| Max length of pipe | 6500mm | ||||

| Power of laser | 4000W/3000W/2000W/1500W/1000W | ||||

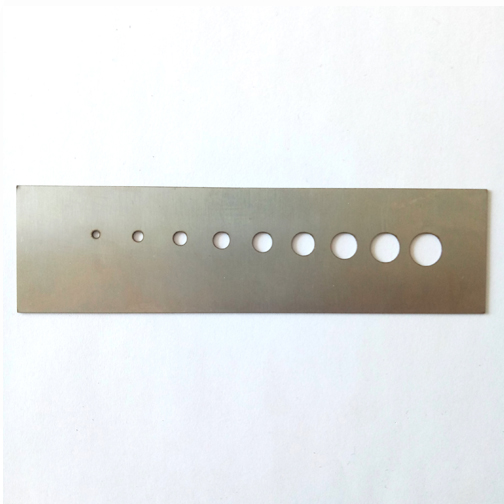

| Effective cutting diameter of pipe | φ20-φ230mm | ||||

| Positioning accuracy | 0.05mm | ||||

| Repetition positioning accuracy | 0.03mm | ||||

The above data is for reference only and is subject to the actual product.

Low energy consumption and low cost of use;high stability, convenient maintenance,

and low maintenance cost

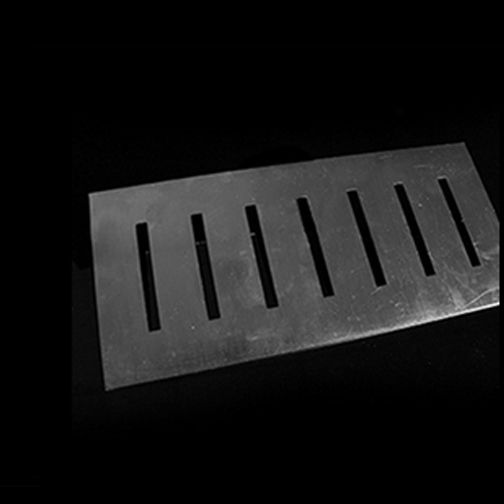

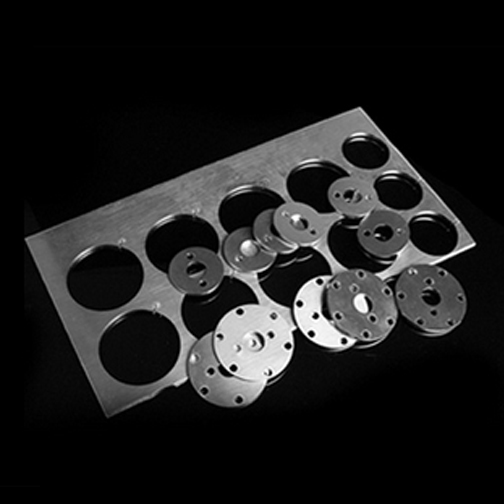

high cutting quality, no noise; high speed, high efficiency, cutting speed up to tens of meters per minute for thin plate; high quality cutting edge, small deformation, flat and beautiful appearance;high speed, high efficiency, cutting speed up to tens of meters per minute for thin plate;high quality cutting edge, small deformation, flat and beautiful appearance

Realize the comprehensive positioning of guide rail,

with high quality machining process Stable machining accuracy and efficient cutting ability

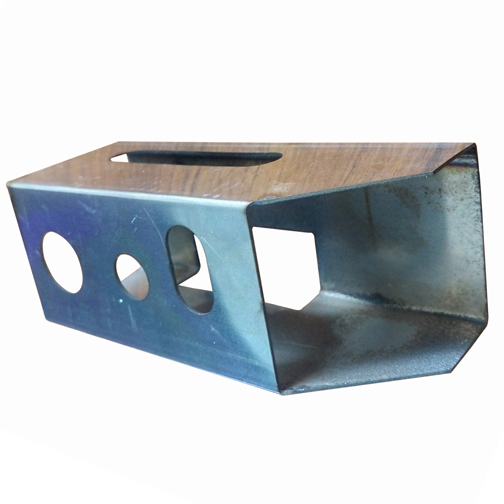

Residual material collection box After the workpiece is processed, the residual materials are collected to facilitate waste recycling or subsequent processing.

Servo motors Excellent performance Increase and improve vibration suppression to improve follow-up performance and cut set-up time New-type advanced automatic tuning function for stable operation Regularly equipped with 5 command modes

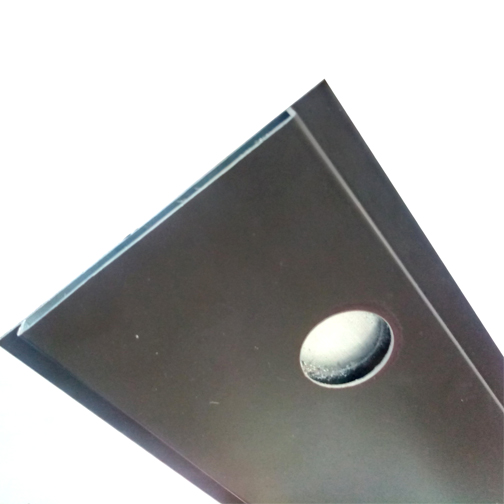

Automatic zoom laser cutting head The laser head is adjusted with two-point alignment, and the focus adjustment is driven by imported motor. In terms of perforation, the efficiency is significantly improved. The lens are protected in drawer type for easy replacement.

Intelligent travel protection Automatically monitors the traveling range of the motion module, responsively and quickly.At the same time the risk of operation is reduced to the lowest with a hard limit as a additional safeguard

Intelligent control software Intelligent layout for cutting graphics;Multi-type graphics import;Automatic optimization of cutting sequence; Intelligent edge-tracking, automatic positioning;Improve the utilization of materials, reduce waste; Simple and fast system operation, accurate cutting instructions, making better user experience

Intelligent alarm system The multi-directional abnormal alarm of the device is directly transmitted to the panel, the device fault is known in advance, and the hidden danger is reduced, make the equipment abnormal troubleshooting efficiency doubled

with modern production workshop and necessary equipments

Nowadays, with the increasing development of science and technology, as a mature CNC equipment manufacturing enterprise, VIOOO Laser will continue to adhere to the business philosophy of “survive by quality, develop by reputation”, the management attitude of“rigor and pragmatism”, and the mission of improving production efficiency by technological innovation, to provide customers with better CNC equipment and solutions.

VIOOO Laser is on the way to success.You are on the way to success too accompanied by VIOOO Laser.